4 Simple Techniques For Aws Cwi

4 Simple Techniques For Aws Cwi

Blog Article

Not known Factual Statements About Aws Cwi

Table of ContentsSee This Report about Aws CwiGetting My Aws Cwi To WorkThe Ultimate Guide To Aws CwiUnknown Facts About Aws CwiLittle Known Facts About Aws Cwi.

Third-party quality assurance evaluation of steel construction fixate welding examination, along with evaluation of bolting and paint of architectural steel. KTA's steel examiners supply High quality Control (QC) assessors to supplement maker's/ professional's in-house QC staff and on projects that mandate preserving the solutions of a qualified inspector (e.g., CWI) employed by an independent assessment company.Examiners conduct aesthetic evaluations of product for uniformity with the approved requirements, plans and codes, in addition to confirmation of Qualified Material Examination Records (CMTR) for materials utilized. Materials and elements are observed at bottom lines along the production process in both steel mills and steel construction stores. KTA's qualified welding inspectors likewise witness welder and welding procedure qualification tests as suitable to the range of the project.

Steel fabrication evaluation services likewise routinely include carrying out non-destructive screening (NDT), also referred to as non-destructive evaluation (NDE), including Magnetic Particle Evaluating (MT), Ultrasonic Testing (UT) and Liquid Penetrant Examining (PT) (AWS CWI). Assessments occur in steel mills and construction stores throughout the United States and on-site in the field and consist of all ranges of structures including bridges, arenas, structures, towers, posts, and indicator frameworks

What Does Aws Cwi Do?

KTA offers examination solutions for the fabrication of bridge girders, bearings, grid deck, indicator structures, light and traffic poles, pedestrian bridges, and various other freeway components. KTA also supplies these solutions for manufacture of architectural steel for buildings, containers and pipelines. KTA's evaluation services include coating examinations covering surface area prep work, painting, galvanizing, and metalizing.

KTA's philosophy is to react quickly to customers' demands, match the best examiner to the task, and give the requisite documentation. KTA has the support workers to provide technological consulting to the area personnel and to the client. KTA has specialists readily available to seek advice from on welding, NDT and finishes.

FST Technical Provider is your worldwide partner in the Semiconductor and Drug Industries! Our positions consist of advantages such as clinical, oral, vision, life, 401(k) with business match, PTO, paid holidays. Come join an amazing group in an interesting, fast paced, and ever-growing industry! We are looking for a CWI's and/or NDT Level II accredited Welding Inspectors from in and around the Lithia Springs, GA area! Town candidates are motivated to apply but this position is open to tourists with mobilization and regular monthly daily for those living outside the area.

The Of Aws Cwi

Perfect prospect will certainly have high pureness piping evaluation experience. CWI's and NDT Degree II's highly urged to apply.

Pro QC's third-party welding inspection solutions consist of: Paper Testimonial Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Screening (NDT) Others Our welding inspection reports are supplied within 24 hr and record all examination factors relevant to high quality, including all determined weld blemishes and digital pictures (Welding Inspection Company) (https://www.reverbnation.com/awscw1w3lding). Pro QC's group of assessors provides third-party welding assessments around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and recommended you read a lot more nations

Inspection of the welding job is essential for correct high quality When your company is handling significant tasks with requirements for 3rd party independent welding inspection, we provide exceptional welding witness inspection services to verify that welding has actually been carried out according to most used welding requirements and specifications. AQSS carries out welding examination services for customers from a selection of sectors.

Aws Cwi Things To Know Before You Get This

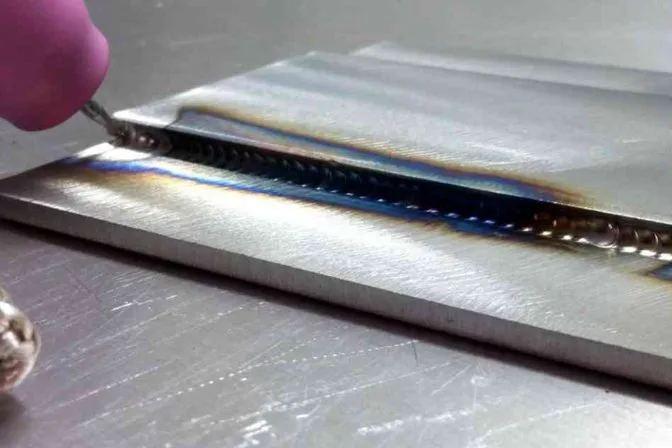

Not complying with properly qualified welding procedures commonly leads to a weld of poor high quality, which can increase the fabrication's likelihood of failure under desired service conditions. By inspecting for defects, our inspectors can help clients ensure that their welds fulfill pertinent requirements of top quality guarantee (Certified Welding Inspector). Weld evaluations are conducted for several factors, one of the most typical of which is to establish whether the weld is of suitable top quality for its designated application

The code and standard made use of depends on the market. Our welding assessors have actually the called for qualifications with years of experience with inspection and are familiar with most applied welding standards and requirements. AQSS has CWI certified inspectors. We execute these solutions making use of a range of nondestructive screening (NDT) methods: The inspection is done based on pertinent codes, such as American Welding Society (AWS), American Culture of Mechanical Designers (ASME), and Military (MIL-STD) common specs.

Aws Cwi - Questions

Normally, our inspectors are inspecting for cracks, pits, surface pores, undercut, underfill, missed out on joints, and other elements of the weld.

Samples can likewise be taken at intervals during the production procedure or at the end of the run. Harmful screening examples are specifically cut, machined, ground, and brightened to a mirror-like coating. An acid etch is then applied to aesthetically highlight the weld, and the example is then checked under a microscopic lense.

Report this page